The Science Behind The Shield

Rhino-Shield™ Ceramic Coating is a durable, flexible, maintenance free exterior wall coating. It is a 100% acrylic waterborne, high build formula that waterproofs, insulates, and soundproofs.

Innovative technology combines 100% acrylic elastomeric resins with urethane resins resulting in a flexible and extremely tough surface. The thick rubber-like membrane actually becomes part of the substrate due to excellent adhesion and bonding.

But how did this super product come to be?

History of Rhino-Shield

History of Rhino-Shield

The owners of Rhino Shield started as home improvement contractors in Destin, the panhandle of Florida, known for its extremes of weather, with smoothering southern heat and humidity, frosty cold, torrential rain and, of course, hurricanes.

Over the years, they sold and applied many different paints and coatings, including national brand paints, and even proprietary coatings with long term warrantees.

They were one of the "good guy" contractors—the kind of company that actually went back and took care of customers, fixing issues with the paints and coatings they applied as problems occurred.

After a while, the contractors found that the cost of repeat visits and fixing paint and coating problems was not cost effective. In fact, it was costing them a fortune. Service calls in the painting industry are expensive to the contractor. They needed a more durable paint or a better way to apply it.

They hired a chemist to help determine if the problems were due to materials or their application. The chemist could find no immediate fault in their methods, “You are using a lot of good materials and you are certainly preparing the home and applying the product according to the manufacturer’s specifications.”

So the chemist broke down the paints and coatings they were using and discovered that they were full of fillers such as the clays, extenders, and vinyl you find in almost every paint or coating. He reported his findings to the contractors.

So the chemist broke down the paints and coatings they were using and discovered that they were full of fillers such as the clays, extenders, and vinyl you find in almost every paint or coating. He reported his findings to the contractors.

“The manufacturers of these paints and coatings are using too many fillers. After two, three, or four years, these fillers are degrading and causing your problems.”

The chemist suggested developing a coating with no fillers and less water. He explained that in a paint or coating, after the water evaporates you are left with only the solids. In the best scenario, if those solids are the resins, pigments and ceramics that are active parts of the coating, then you have a coating that won’t break down like traditional paints.

So they developed the first generation of what was later to be called “Rhino-Shield”. It ended up costing the contractors a lot more per gallon to have this type of coating manufactured for them, but they found that it saved a lot more money in the long run not having to do all the service calls. Homeowners appreciated that even more.

After their initial successes with the product, they wanted to improve it further. So they choose to use the superior 3M Ceramic Micro-Spheres to make Rhino-Shield better.

Since then, Rhino-Shield has spread across homes throughout the USA with dealers in nearly every state. Advanced Exteriors is the exclusive Rhino-Shield dealer for Southern California.

Ceramics

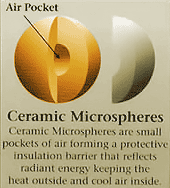

Ceramic Micro spheres were invented in the early 1960’s by the 3M Company as an outgrowth from the manufacture of solid ceramic beads. Because the micro spheres are made from ceramics, they provide the additional benefits of high heat and chemical resistance.

The central air pocket in the micro spheres provides an insulating barrier for your walls much like a thermos bottle does. This insulating, industrial maintenance-free coating is long lasting, offering superior mildew resistance, corrosion resistance, and ultra-violet ray reflectivity.

Rhino-Shield uses 3M Ceramics which incorporate different sized microspheres as fillers. Conventional paints utilize inexpensive mineral products as fillers that are irregular in shape and size. These irregularly-shaped fillers don’t pack nearly as well as a mix of small and large microspheres. (The smaller spheres pack more tightly into the spaces between the larger spheres.) The more densely the coating is packed with microspheres, the less permeable it is to stains and the thicker it is when dry.

Adding 3M ceramic micro spheres and high quality Titanium Dioxide to our top grade 100% acrylic elastomeric resins makes Rhino Shield reflect more light and heat, repel water better, and is more durable than any other coating on the market.

Ongoing testing and constant improvements ensure that Rhino Shield will remain the absolute best exterior coating for your home.

For a complete look at the science of Rhino-Shield Ceramic Coatings, please call today and speak to one of our experienced representatives.

Unique Adhesive Primer Sealer (APS)

When Rhino Shield was designing their primer they told the chemist, "Cost is of no concern, just make us the best primer possible."

The result was the only primer on the market that will stay tacky for up to 3 weeks.

If you apply any other primer, it will be dry to the touch in just a few hours - there is no tacky feeling left. They rely totally on a chemical reaction to make the primer and paint "set".

So what does that mean? It means that Rhino Shield's primer does not have to rely on only a chemical reaction to make it all stick together. The tacky feeling is a glue like adhesion making the coating bond together and become a cohesive system.

No other primer can match it!

Testing Data for the Ceramics Product

In addition to excellent durability, Rhino-Shield uses 3M ceramic microspheres to help insulate your home. This qualifies Rhino-Shield as a "Low-e" coating. Most paints and coatings use inferior mineral filler and chalk (CaCO3-calcium carbonate) as fillers which allow heat to quickly transfer. By comparison, ceramics prevent heat transfer and offer superior insulating benefits.

Ceramics Thermo Conductivity. This test data compares the thermal conductivity of CaCO3 versus W410 and K46 ceramic microspheres.

BASF Testing. Rhino-Shield Ceramic Coating is rigorously tested by tested by BASF and a series of independent labs to ensure quality, consistency, and dependability. Rhino-Shield Ceramic Coating meets or exceeds requirements in the following categories:

| Physical Property | ASTM Test Number |

|---|---|

| Dry Adhesion | C 794/ D 903 |

| Elongation | D 2370 |

| Flexibility | D 522 |

| Fungi resistance | G 21 |

| Permeance | D 1653A |

| Salt Spray | 8-117-97 |

| Surface Burning Characteristics of Building Materials | E 84-03b |

| Tear Resistance | D 624 |

| Total Emittance and Spectral Reflectance | E408-71 |

| Tensile strength | D 2370 |

| Viscosity | D 562 |

| Water swelling | D 471 |

| Weathering | ** |

| Wet Adhesion | C 794/ D 903 |

| Weight of solids | D 1644 |

BASF is one of the largest and most respected chemical companies in the world. They are recognized by the slogan “We don't make a lot of the product you buy, we make a lot of the products you buy better”. BASF has permformed several rounds of testing on Rhino-Shield. Rhino-Shield excels at flexibility, tear resistance, tensile strength, breathability, and viscosity. Addtionally, BASF performed an accelerated aging test. At the end of the test Rhino-Shield showed no visable signs of aging and maintained its elastomeric properties. View the BASF Testing Results (PDF).

Class A Fire Rating

Rhino-Shield has a class A fire and smoke rating. In some areas of the country prone to wildfires, buildings with a class A fire rating may qualify for a discount on their homeowners insurance.

Salt Tolerance

Rhino-Shield is the most salt tolerant coating on the market. This is vital in coastal areas. As the testing shows, we are in the top category of salt tolerance and even outperformed the industry standard, Rustoleum. View the Salt Spray Testing Results.